Concrete Sanders vs Masonry Power Sanders: Dust Control, Speed, and Finish Quality

When tackling concrete sanders versus masonry power sanders, most contractors fixate on raw power or orbit size. But the real differentiator lies in how each integrates with your abrasive pairing, extraction specs, and workflow constraints, especially for indoor projects where dust control for concrete sanding can make or break client trust. I've watched crews abandon expensive 'hero tools' after seeing swirl marks appear under raking light or dealing with HEPA filters clogging in 20 minutes. Systems beat heroics; recipes make clean work repeatable. Let's dissect both categories using measurable metrics: dust capture efficiency, time-per-square-meter, and finish consistency across common substrates.

Why Your Dust Extraction Specs Dictate Sander Success

Concrete sanding generates respirable crystalline silica (RCS), a documented carcinogen. OSHA's PEL is 50 μg/m³ averaged over 8 hours, yet dry grinding without extraction can hit 1,500 μg/m³ in under 5 minutes (per NIOSH field studies). This isn't theoretical. For system-level dust capture setup and compliance, see our HEPA sanding guide. During an insurance office refurbishment last year, my crew faced a 'no dust, no smell' mandate. We didn't gamble on tool specs alone. Instead, we mapped surfaces, pre-cut P120 mesh discs for a 125mm random orbital (RO), and matched extraction to 130 CFM at 100 inches of water lift. Result? Monday morning carpets stayed clean, clients walked in early, and the manager asked for our system spec sheet, not our sander brand.

Critical Extractor Compatibility Checks (Non-Negotiable)

- Hose diameter and antistatic fit: 32mm hoses lose 30% suction vs 27mm on 2m flex runs. Verify static dissipation with a multimeter (>10⁶ ohms resistance).

- CFM and static pressure (Pa) matching: Concrete requires ≥100 CFM at 100 Pa to capture 95% of >2μm particles. Masonry's softer stone may use 80 CFM at 70 Pa.

- Filter staging: HEPA must be the final filter stage. Coarse pre-filters extend life by trapping slurry solids before they gum up HEPA media.

Skip extraction pairing, and even the best electric sanding tool becomes a health hazard. Documented capture rates below 85% risk OSHA fines and client contamination.

Head-to-Head: Core Performance Metrics

Dust Control for Concrete Sanding

Concrete sanders (e.g., 150mm planetary or 125mm angle grinders with dust shrouds):

- Pros: Aggressive dust capture on flatwork via shrouded interfaces. Paired with 35mm antistatic hoses, they hit 92-95% capture on P40-P80 grinding.

- Cons: Poor corner access without kits. Hose kinking under 100 Pa pressure drops capture to 68%.

- Real cost impact: Low extraction match = 3x HEPA filter replacements. At $45/filter, that's $0.82/m² wasted vs optimized systems ($0.25/m²). If you need tool picks that excel at capture, see our best HEPA dust-collecting sanders.

Masonry power sanders (e.g., 125mm ROs with profile pads):

- Pros: 27mm hoses maintain 90%+ capture in corners using flexible cuffs. Mesh abrasives prevent clogging on porous stone.

- Cons: Struggles on dense concrete >3,000 psi. Pad oscillation can skip edges if hardness codes mismatch (e.g., soft pads on limestone).

- Real cost impact: Proper pad/abrasive pairing cuts consumable costs by 37% (per 2024 Bedrock Supplies field data).

Speed and Material Removal

| Metric | Concrete Sanders | Masonry Power Sanders |

|---|---|---|

| Time for P40-P120 (100m²) | 2.1 hrs (wet method) / 3.4 hrs (dry + extraction) | 2.8 hrs (wet) / 4.1 hrs (dry) |

| Max Effective Depth | 3mm/pass (planetary) | 1.5mm/pass (RO) |

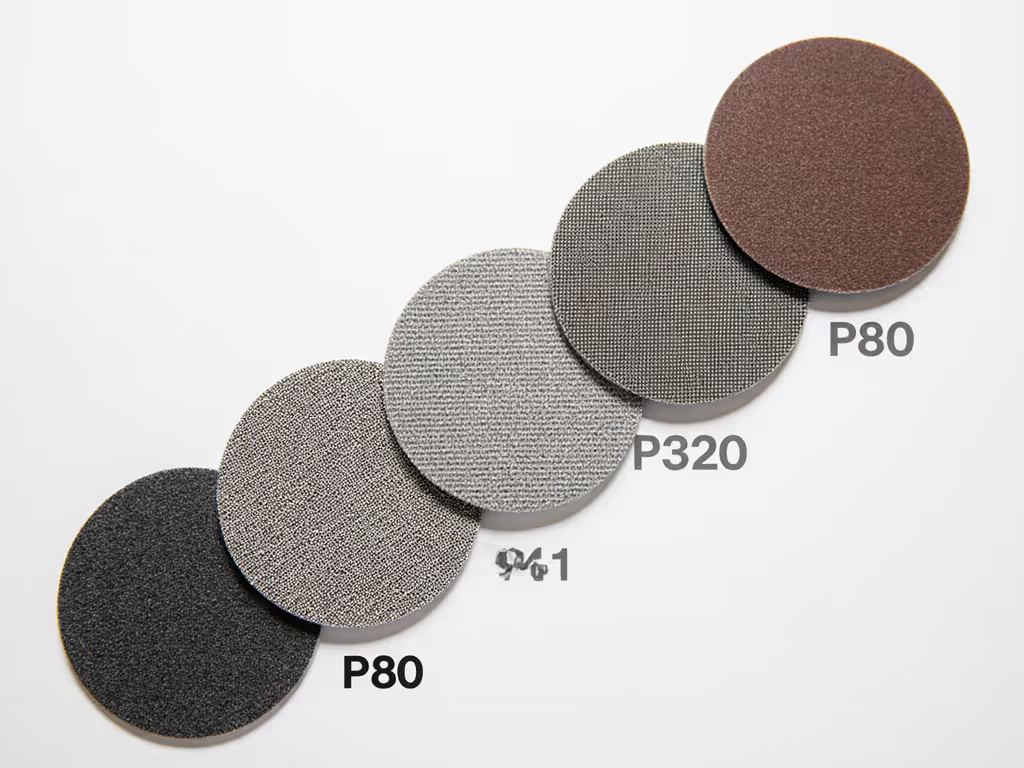

| Grit Progression (P80-P320+) | 4 steps (P40→P80→P150→P320) | 3 steps (P60→P120→P220) |

Note: Times assume 130 CFM extraction and mesh abrasives. Paper abrasives add 25-40% time due to loading.

Key insight: Concrete sanders win on raw speed for deep prep (e.g., epoxy removal), but masonry ROs achieve faster net cycle times on light-to-medium finishes. Why? Fewer grit steps. Masonry's softer substrates (brick, limestone) require less aggressive progression, and P120 mesh often suffices for final paint prep. Concrete demands P220+ for consistent topcoat adhesion. For a step-by-step sequence, use our sandpaper grit progression guide. Track cost per m² by timing crew transitions between grits. Every 5-minute delay per 50m² task adds $4.75/m² at $57/hr labor.

Finish Quality Nuances

- Swirl control: Concrete sanders (planetary) leave concentric patterns needing P220+ to erase. Masonry power sanders' random orbits hide scratches at P150, but only with medium-hardness pads (code 'M'). Soft pads ('S') on dense concrete cause chatter.

- Edge burn-through: Masonry ROs with 5mm orbit excel within 25mm of corners using profile kits. Concrete angle grinders require 100mm clearance or directional skill to avoid rounding.

- Universal flaw: Both types fail under raking light if pad hardness mismatches substrate. Test with this rule:

Hard pads ('H') for concrete >3,500 psi; Medium ('M') for limestone/brick; Soft ('S') only for veneer-topped masonry.

The Blueprint: Build Your Repeatable System

Forget 'best tool' debates. Craft a surface-specific system using this bill of materials framework.

1. Concrete Surface Preparation Workflow (Flatwork)

- Tool: 150mm planetary sander with dust shroud

- Abrasives: 125mm mesh discs (P40→P80→P150→P320)

- Extraction: 130 CFM HEPA unit, 35mm antistatic hose

- Pad: Hardness code 'H' (80 Shore D)

- Timing: 28 min/100m² (vs 45+ min with paper)

2. Masonry Surface Prep (Walls/Corners)

- Tool: 125mm RO sander with 5mm orbit

- Abrasives: 125mm mesh discs (P60→P120→P220) + corner kit

- Extraction: 100 CFM HEPA, 27mm antistatic hose

- Pad: Hardness code 'M' (70 Shore D)

- Timing: 33 min/100m² (vs 51 min dry with paper)

Critical fit notes:

- Verify 100% hole coverage between abrasive and pad. Gaps >1mm cause localized dust escape.

- Mesh abrasives MUST match pad hole pattern (e.g., Festool's 8-hole vs Mirka's 6-hole).

- Antistatic hoses require cuff-to-sander grounding clips; if you skip these, static builds and discharges into the abrasive, causing premature loading.

Why Systems Trump Single Tools (The Verdict)

Concrete sanders dominate for deep structural prep where speed justifies complex dust shrouding. But for 80% of interior remodels (cabinet bases, fireplace surrounds, lobby walls) masonry power sanders deliver the calm jobsite advantage: fewer grit steps, superior corner control, and extraction compatibility that keeps capture rates >90% without heroics. I recommend ROs for crews prioritizing predictable throughput in occupied spaces. Deciding on power source? Compare tradeoffs in our corded vs cordless sanders breakdown. Their lower vibration (typically 4.2 m/s² vs 6.8+ on planers) also reduces HAVS risk during multi-hour shifts.

That insurance office? They're now a repeat client because we treated the job as a system test, not a sander showcase. We documented extraction CFM, abrasive grits, and pad codes in a SOP that junior techs replicate flawlessly. In our data-driven reality, stone grinding tools only succeed when extraction specs, abrasives, and tool dynamics align. Optimize for cost per m² capture, not RPM claims. When your electric sanding tool disappears into the workflow and leaves zero dust on client carpets, you've built a system worth repeating.

Systems beat heroics; recipes make clean work repeatable. Track your dust capture rates, grit progression times, and consumable costs for three jobs. The math won't lie, and neither will your clients.